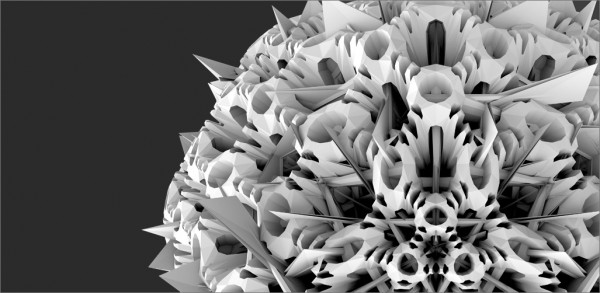

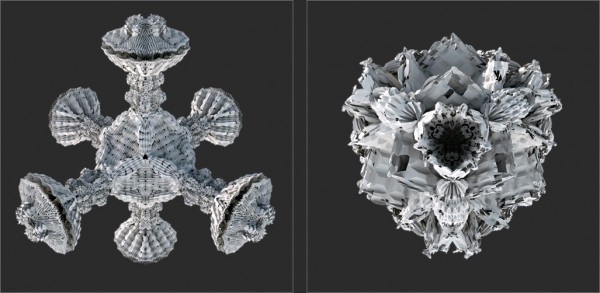

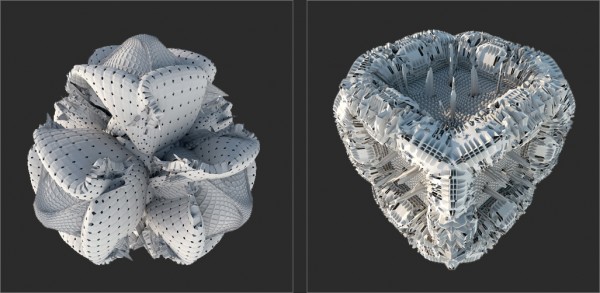

The Platonic Solids project by computational architect Michael Hansmeyer

explores how a purely operations-based geometric process can generate

complex form. Rather than studying the possibilities in combining

numerous primitives, this project examines the potential inherent in a

single primitive given an appropriate process. It takes the most

primitive forms, the platonic solids, and repeatedly employs one single

operation – the division of a form’s faces into smaller faces – until a

new form is produced.

All of the forms shown are generated using the same single process,

only the variables that control the process’ division operation are

allowed to change. This single process affects both the form’s

topography and topology. It influences attributes such as the degree of

branching, porosity, and fractalization – just to name a few. The

process also works at multiple scales: it affects not only the overall

shape, but it determines the surface development as well as the

generation of miniscule textures. The resulting forms display a novel

aesthetic and an astounding complexity that largely defies attempts at

reductionism.

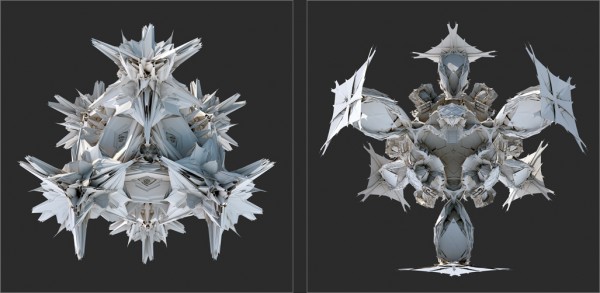

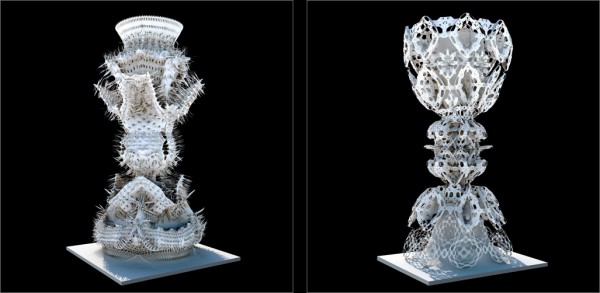

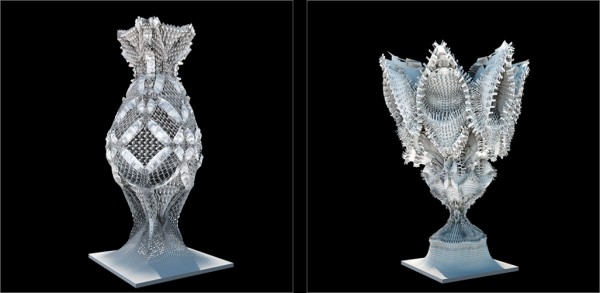

This project by computational architect Michael Hansmeyer

involves the conception and design of a new column order based on

subdivision processes. It explores how subdivision can define and

embellish this column order with an elaborate system of ornament. An

abstracted doric column is used as an input form to the subdivision

processes. Unlike the minimal input of the Platonic Solids project, the

abstracted column conveys a significant topographical and topological

information about the form to be generated. The input form contains data

about the proportions of the the column’s shaft, capital, and

supplemental base. It also contains information about its fluting and

entasis.

The input form is tagged to allow the subdivision process to

distinguish between individual components. This allows a heterogeneous

application of the process, with distinct local parameters settings. In

addition to distinguishing among tagged components, the process

parameters can be set to vary according to the input form’s topography

as well as its topology. Finally, an environmental specification of

parameters is possible to allow regional phenomena to occur.

The result is a series of columns that exhibit both highly specific

local conditions as well as an overall coherency and continuity. The

ornament is in a continuous flow, yet it consists of very distinct local

formations. The complexity of column contrasts with the simplicity of

its generative process.

A full-scale, 2.7-meter high variant of the columns is fabricated as a

layered model using 1mm sheet. Each sheet is individually cut using a

mill or laser. Sheets are stacked and held together by poles that run

through a common core. The calculation of the cutting path for each

sheet takes place in several steps. First, the six million faces of the

3D model are intersected with a plane representing the sheet. This step

generates a series of individual line segments that are tested for

self-intersection and subsequently combined to form polygons. Next, a

polygon-in-polygon test deletes interior polygons. A series of filters

then ensures that convex polygons with peninsulas maintain a mininimum

isthmus width. In a final step, an interior offset is calculated with

the aim of hollowing out the slice to reduce weight. While the mean

diameter of the column is 50cm, the circumference as measured by the

cutting path can reach up to 8 meters due to jaggedness and frequent

reversals of curvature. The initial prototype uses 1mm grey board. Tests

using ABS, wood, as well as metal are under way.

Источник: http://www.evolo.us/architecture/algorithmic-column-with-six-million-faces-michael-hansmeyer/ |